EPOXY conductive flooring(1.0-3.0MM)

Features: easy and quick construction, acid-base resistance, wear and abrasion resistance, long durability

Application scope: Electronic plant, clean room, instrument & control room, computer room, hospital, office building, packaging room and other light industry and light load floors

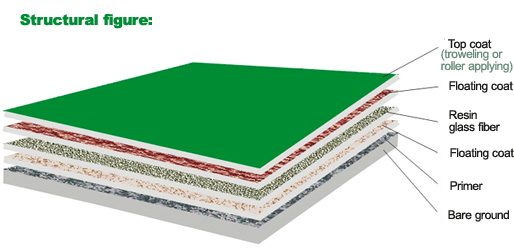

Engineering methods:

1、Bare ground treating: clean and grind the new and old floor surface, remove the smoothened layer with hollowing, fill the surface pit and cavities, make sure no oil stain, coating or material easily adhesion to concrete on the surface.

2、Primer construction: primer base and hardening agent are batched according to the ratio required and uniformly mixed, and applied uniformly on the treated floors with a roller or trowel.

3、Intermediate coat construction: batch the intermediate coat base and hardening agent according to the ratio required, add filling material and mix uniformly; use a trowel to apply the material on the floor already applied with primer to increase the thickness and strength.

4、Copper foil paving: paving copper foil on the ground surface according to the design specification, with earthing treating done.

5、Conductive primer: mix and agitate conductive primer base and hardening agent according to the ratio required and uniformly apply the material on the insulating layer.

6、Conductive intermediate coat: batch the intermediate coat base and hardening agent according to the specified ratio, add a small amount of filling material and mix uniformly; use a trowel to apply the material on the floor, trim the floor to the allowable evenness.

7、Conductive top coat construction: batch and mix top coat base and hardening agent according to the ratio required and apply the mixture uniformly on the floor surface with a roller or trowel.

8、Curing(25℃, minimal 24h)

[Notes:1、Customized design based on the client requirements.2、Slight variation of material proportioning based on different environmental temperature and bare ground moisture. Eversun Technical Department reserves the final interpretation right.]